Manufacturing Services

Manufacturing with Digital Touch

Manufacturing with Digital Touch Since the advent of internet, the way businesses have been run has been constantly changing. The Manufacturing sector has also been making use of the advantages that being part of a connected world gives an organization. Manufacturing sector has been undergoing a rapid digital transformation and we at Kanoo Elite has helped our clients in the manufacturing sector with their digital transformations. The Manufacturing industry players are focusing on reinventing their business models, products, production, and value chain to remain relevant in this digital era. From shift of product drawing from paper to 3D files and storage of data in the cloud, digitization has changed the core activities of the Manufacturing sector. At Kanoo Elite we focus on the following five areas of digital transformation for manufacturing sector. With these we aim to help business undergo a digital transformation for their business. We help businesses uncover previously hidden capabilities and opportunities for our clients using new age technologies. The five areas are the following:

-

RTLS Solutions

RTLS Solutions -

Smart Factory

Smart Factory -

ERP implementation

ERP implementation -

OT Security

OT Security

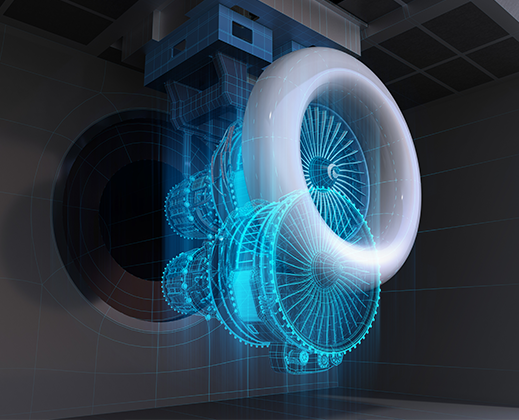

Digital Twins

A digital twin is a digital representation of a machine or a thing. It can show in Realtime what’s happening with the physical twin and predict problem points that may occur. Digital Twins allow for real time awareness and better maintenance planning. Due to the nature of IoT adoption in the manufacturing sector, digital twins can be used across all manufacturing processes leading to entire plants being digitized. This will help in maximizing efficiency across the entire production process.

Real Time Location Systems

Use of Real Time Location Systems allows companies to ensure proper safety protocols. Using RTLS systems also leads to benefits such as identification if broken processes or systems and improving the safety of workers. Most of these systems also allow for the tagging for high values assets within the company. This ensures that these assets are kept where they are needed and ensures that they do not go missing. Using these asset tracking solution overall productivity and efficiency are also increased. Kanoo Elite’s asset tracking solutions can track with very high accuracy levels and low latency. Our solutions are also not intrusive and are highly customizable to meet the demands of all production and logistics environments.

Smart Factory

Use of technology to improve plant efficiency has been in use for decades.

mplementation of Industry 4.0 technologies like IoT, AI and ML based systems in the manufacturing environment has led to a higher control over all the processes. Having this real time picture of what is happening within the environment allows for the operator to be more agile and react faster thereby reducing wastage occurred. Using historical data Kanoo Elite is able advice customers on historical trends and help them achieve higher production efficiency.

ERP implementation

Implement state-of-the art ERP in your manufacturing ecosystem and take the next step in your digital transformation of your business. Improve various aspects for your manufacturing service such as business continuity, supply chain agility, supply chain resiliency, field serviceability among others by using ERP solutions. Having an ERP system allows for all stakeholders within the manufacturing environment to stay connected and allows users to share data. Let us help you in pushing your digital transformation of business the next level. As a managed digital services provider Kanoo Elite has years of experience in implanting ERP systems for our clients.

OT security

In the past OT systems have been kept separate from normal systems. But with the Advent of IOT systems the boundary has been erased. The latest OT systems require the same security measures as regular systems. Operational technology (OT) security is designed to meet the unique security needs of OT environments. This includes protecting system availability, understanding OT-specific protocols, and blocking attacks targeting the legacy systems commonly used in OT environments. Kanoo Elite has years of experience in providing digital risk management solutions and can leverage this experience to ensure that your OT systems do not fall prey to any security breaches that will affect the production.